YRI-V AOI inspection Machine

Yamaha

- Super high-speed 3D inspections

56.8cm²/sec (under optimum conditions) - Super high-accuracy 3D inspections

8-way projector - 4-way oblique imaging inspections

20Megapixels 4-angle camera - Device inspections

Super high-resolution 5μm/coaxial lighting

Super high-speed and high-accuracy inspections

New type of inspection head

The newly developed high-performance inspection head significantly improve the inspection performance of the 2D inspections, 3D inspections, and 4-angle cameras. The inspection performance can be applied to all SMT sectors.

Yamaha’s proprietary high-rigidity frame realizes high-accuracy and super high-speed inspections. The inspection speed is 1.6 to 2.0 times as before, which supports inspections in mass-production.

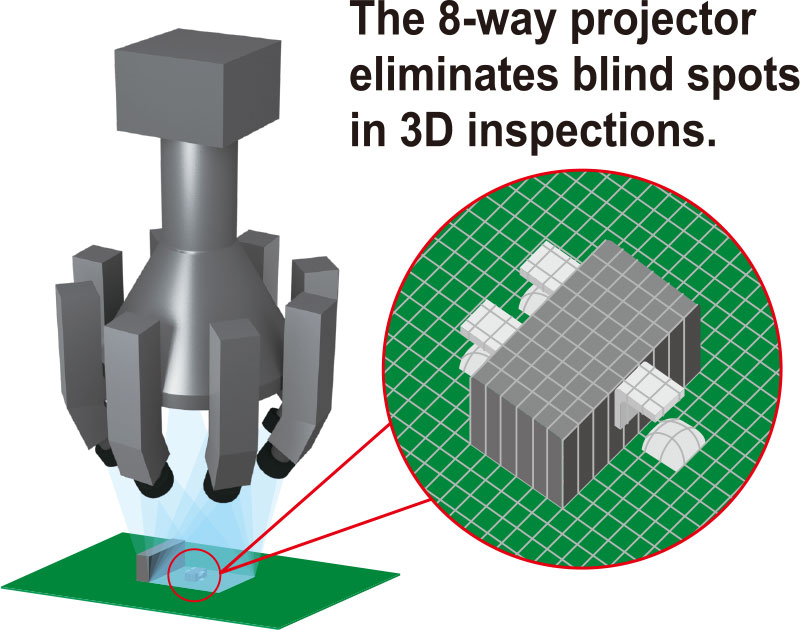

The 8-way projector added to the lineup has enabled inspecting 0201mm components mounted adjacently. The projector reduces the number of blind spots for large components, realizing high-accuracy 3D inspections. The increased 3D measurement range enables 3D inspections of components with heights of up to 25mm.

20Megapixels high-resolution cameras were adopted. Clear images enable accurate secondary judgment. The higher picture quality improves the accuracy of automatic inspections based on oblique images.

New inspection functions required in the inspection process in the device sector were developed. Capable of detecting minute problems such as cracks and chips on semiconductor components (e.g., wafers and WLCSPs), contributing to improving the quality of device products.

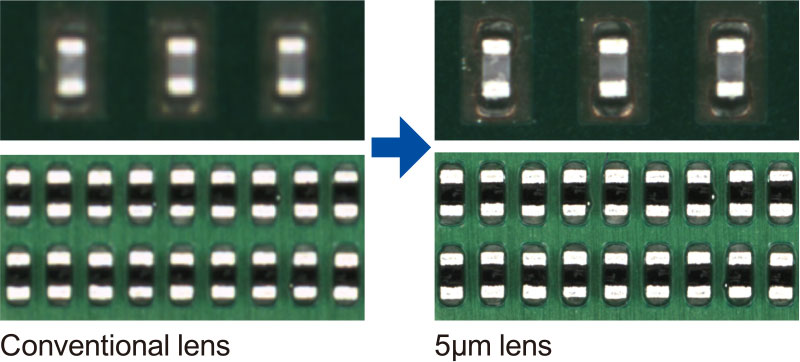

The 5μm lenses added to the lineup are capable of higher definition inspections compared to the conventional 7μm lenses. The lenses improve the performance of high-accuracy inspections of super-tiny components (e.g., 0201mm components) and inspections of minute problems such as cracks and chips on components.

New inspection functions required in the inspection process in the device sector were developed. Capable of detecting minute problems such as cracks and chips on semiconductor components (e.g., wafers and WLCSPs), contributing to improving the quality of device products.

The 5μm lenses added to the lineup are capable of higher definition inspections compared to the conventional 7μm lenses. The lenses improve the performance of high-accuracy inspections of super-tiny components (e.g., 0201mm components) and inspections of minute problems such as cracks and chips on components.

YRi-V can handle large PCBs with L610mm and W610mm as a standard. The dual lane system can convey large PCBs with W320mm on the two lanes

The newly developed dual lane system can operate each lane flexibly. The system that can be easily connected to upstream and downstream equipment contributes to establishing dual-lane lines flexibly.